AUTOMATED INVENTORY MANAGEMENT SYSTEM

Stock control

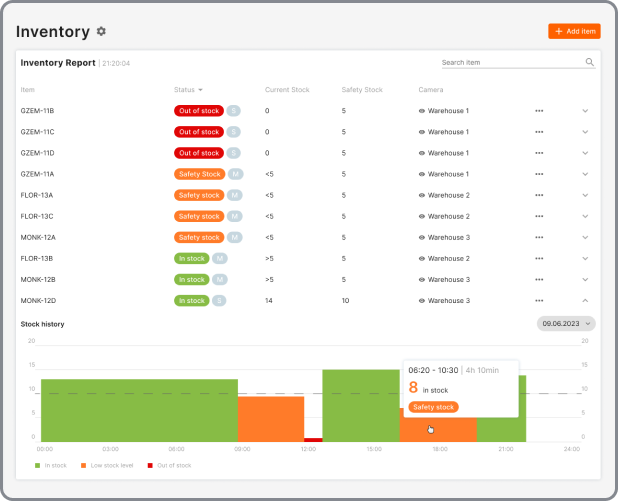

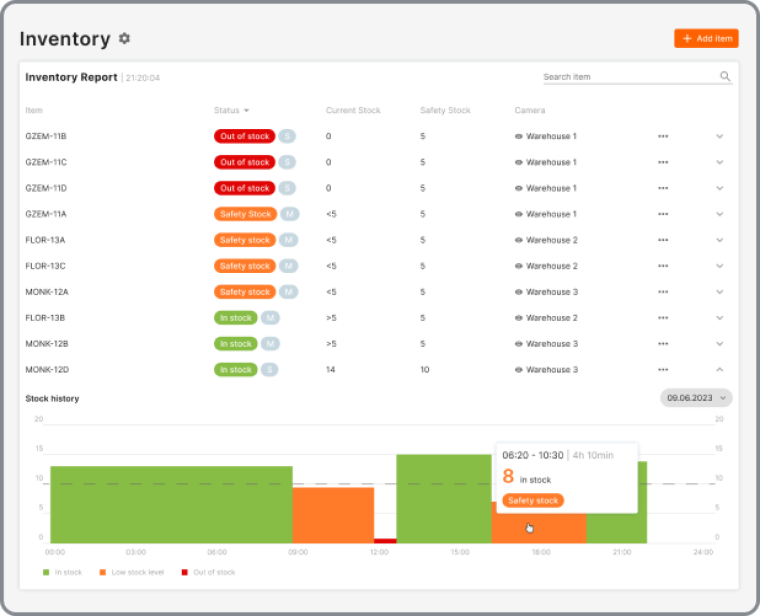

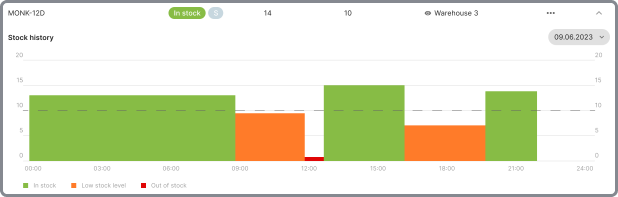

With automated inventory management system managers can effortlessly manage inventory levels and ensure smooth and uninterrupted production processes. Our software helps to facilitate supply chain management and keep up the optimal stock levels by providing real-time inventory tracking and analysis, allowing business executives to create informed decisions and avert costly production line stoppages.Control stock levels via simple and user-friendly interface

Let’s dive into benefits!

FORM THE BASIS FOR MATERIALS PROCUREMENT

INVENTORY FORECASTING

UPGRADE MANUAL REGISTRATION OF INVENTORY WHEREABOUTS

What kind of inventory management and control system do you use?

IMPROVED CUSTOMER SATISFACTION

We make sophisticated technology easy for you to use

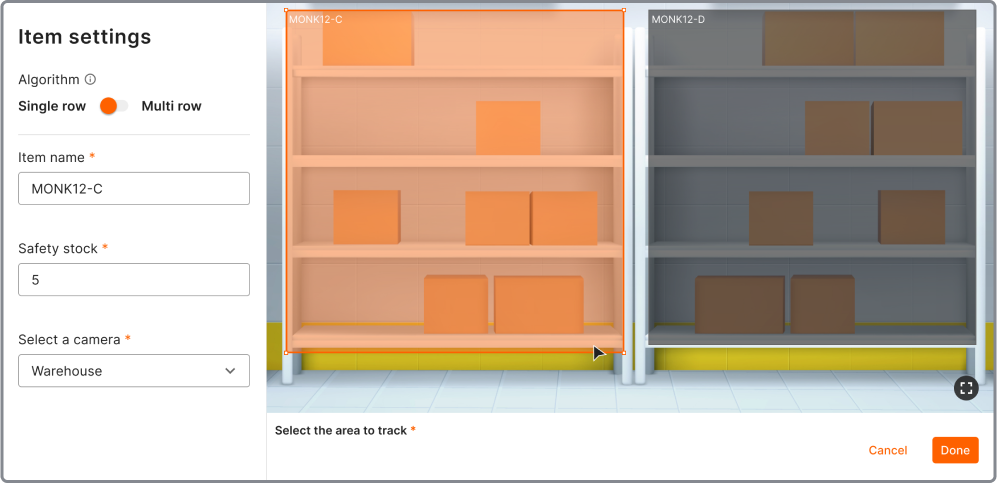

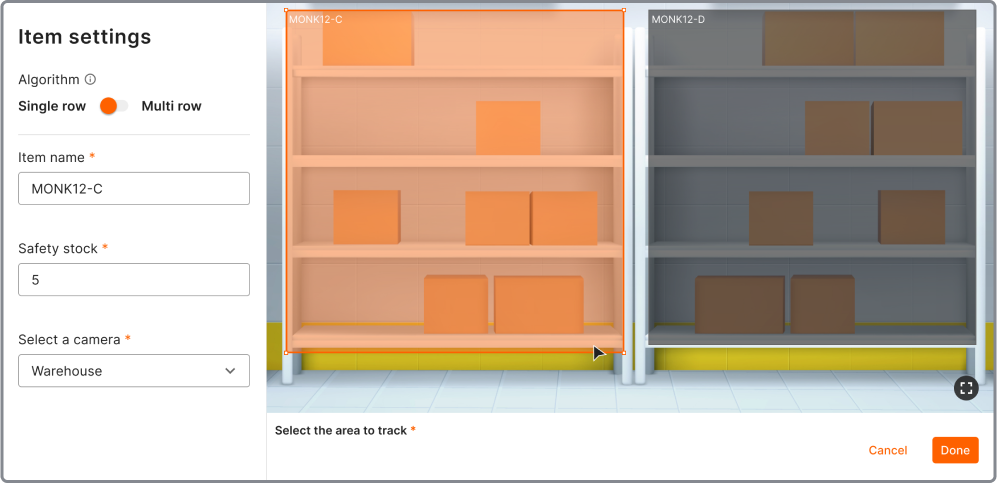

Once you enter the inventory control administrator page and start setting up the process, determine which area you would like to put under control.

You can book a demo version here.

Create item names with different generators and categorize them according to their common inventory attributes.

Automated inventory management system to assist management personnel

Even if your company owns multiple inventory warehouses in different locations, as a manager or management representative you can manage orders and warehouse transfers of stock right from a single system. Digital tools paves the time-saving way to control the movements of the inventory stock item.

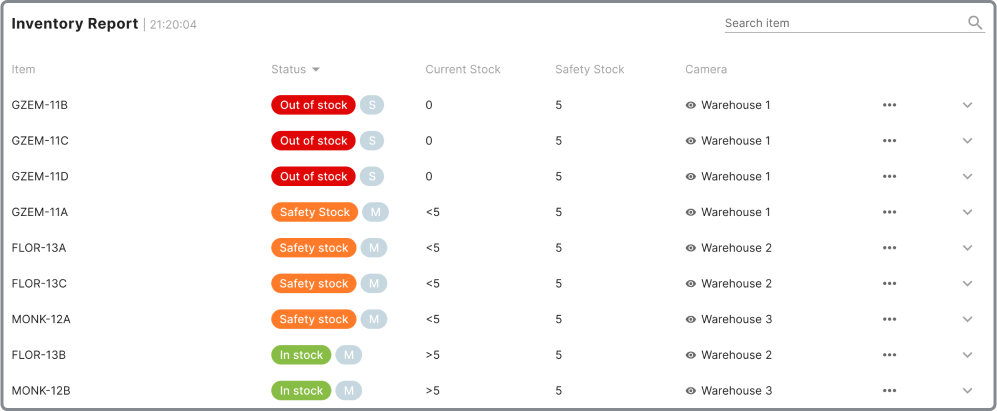

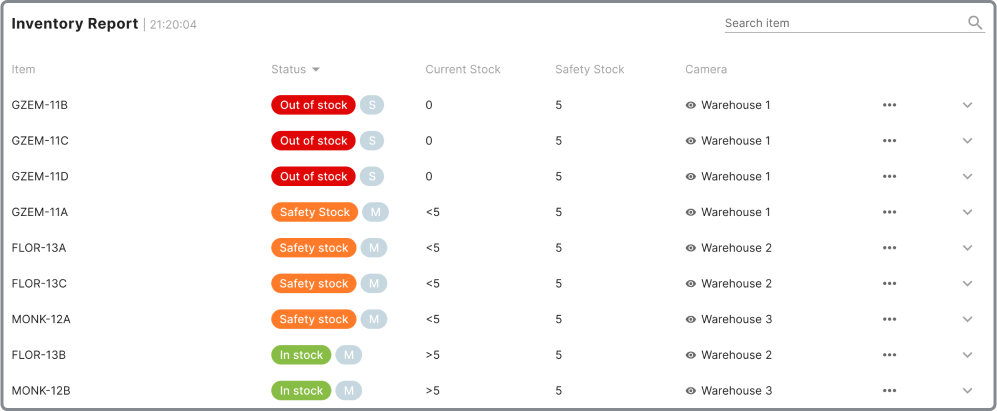

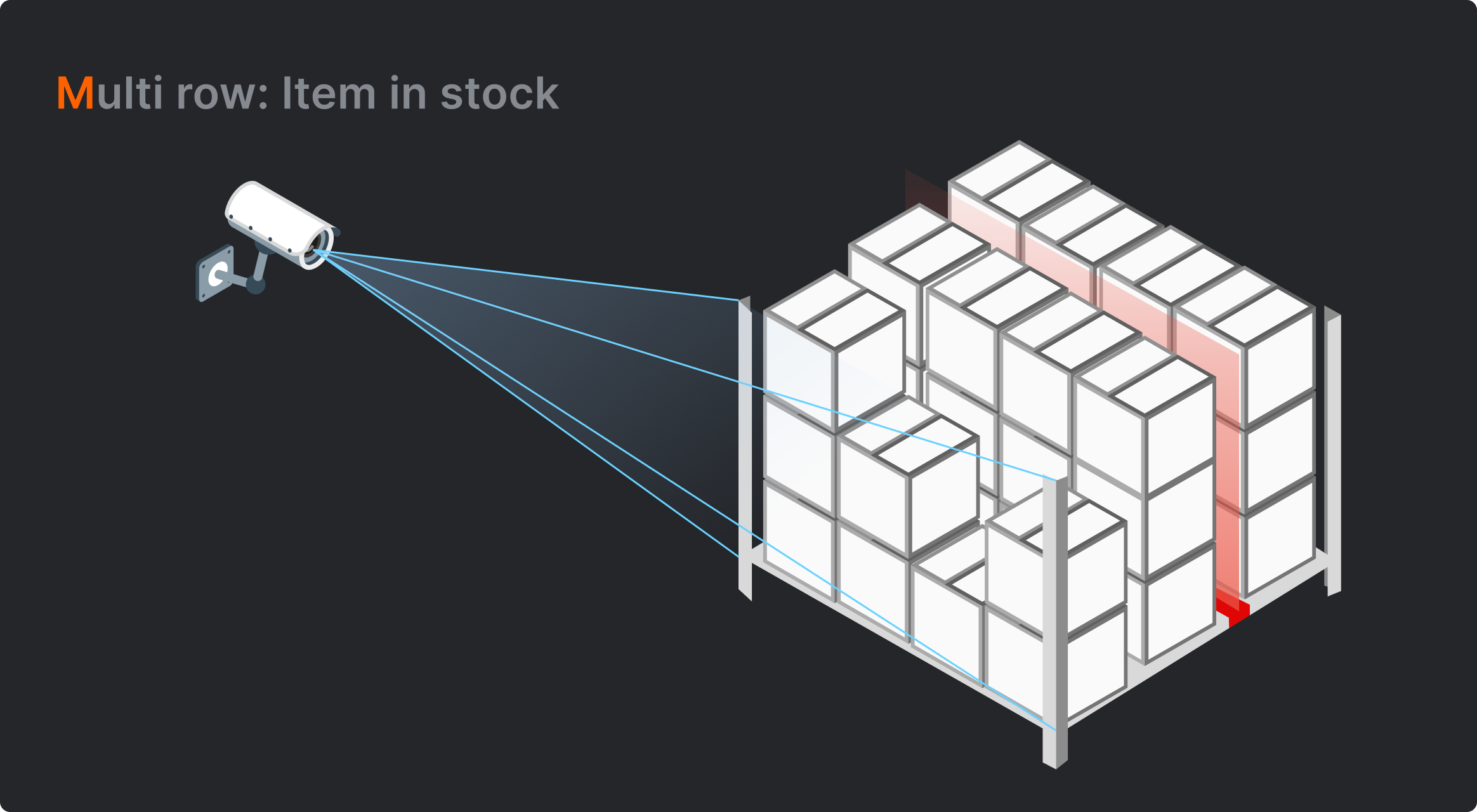

What is S and M in inventory

tracking software?

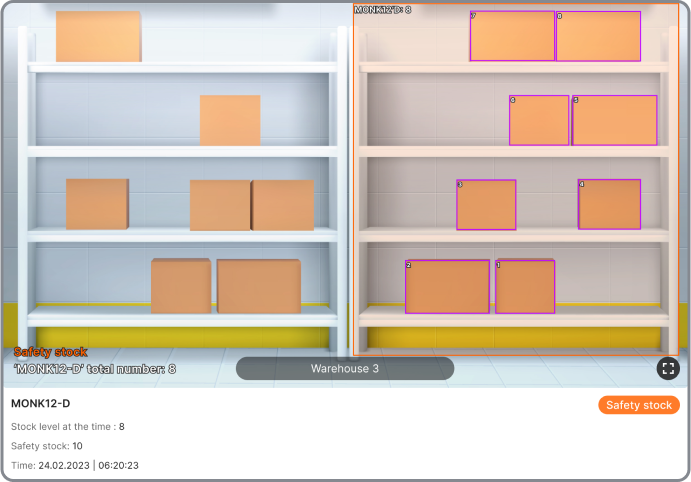

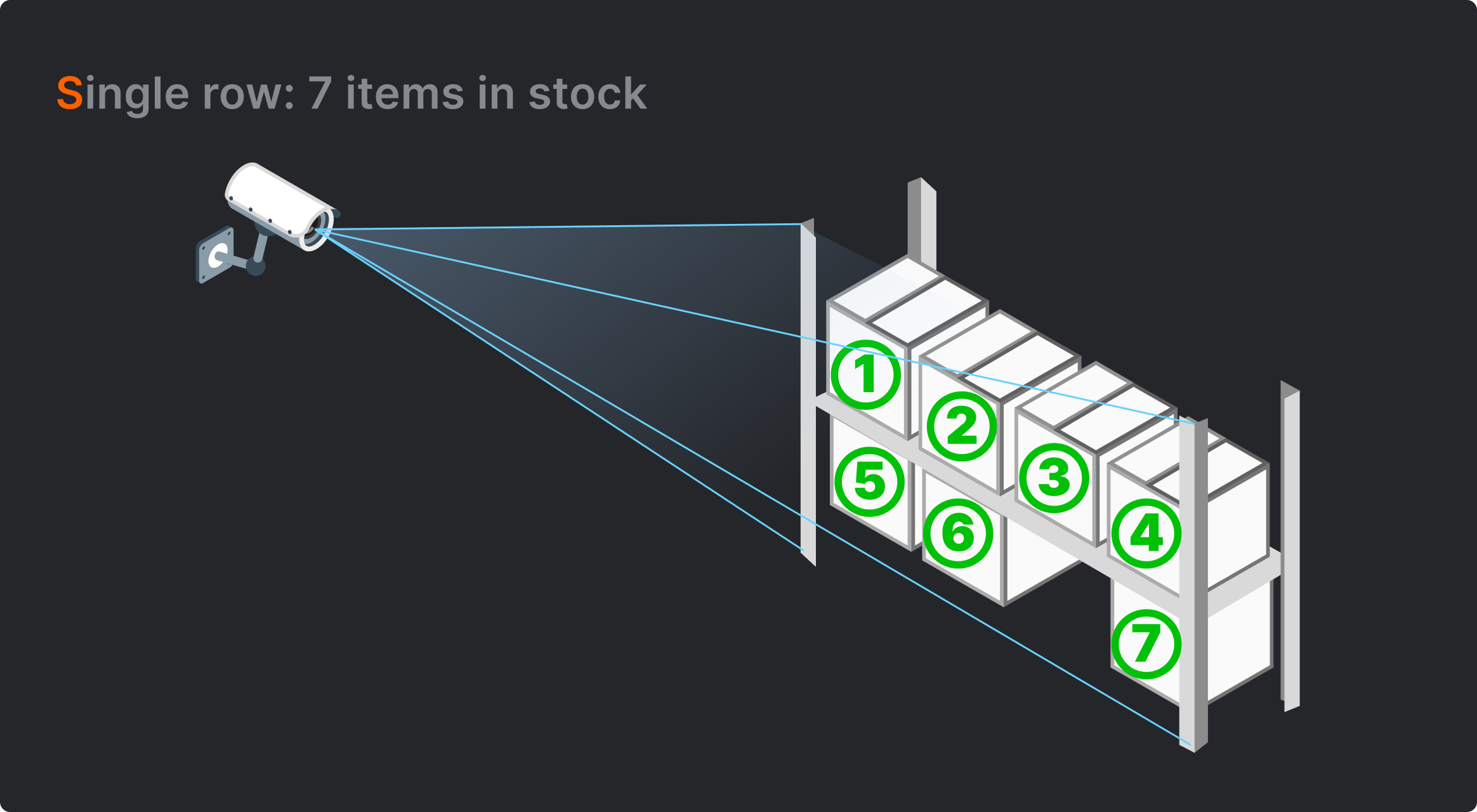

The single-row algorithm is designed to precisely count the number of boxes stacked in one row.

The reason WHY one

should use automation for inventory management systems

Managers enter all data about product movement into an ERP System or Excel spreadsheet. But the quantity of items in the warehouse may not coincide with the figures indicated in the documents, for example, because the specialist wrote off the goods or used them for unplanned needs. That’s why visualization of stock levels comes in handy in addition to the existing stock management system. The example of successful inventory replenishment strategies that resulted in stock costs minimization is described here.

CUSTOM STOCK CONTROL SOFTWARE

Designed for growing businesses

Time-saving inventory tools plus procurement and inventory management software

Control sales and orders

Get a real-time update of all your online inventory transactions and material order status. It is vivid from a centralized dashboard. The centralized inventory dashboard is installed for letting you know how many items have to be packed, how many were shipped. Have it all delivered on a single screen.

Smart automation of manufacturing inventory management

Every business has a lot of crucial reports like sales and inventory purchase history. With our stock control system and its tools all the inventory valuation gets automatically updated on a real-time basis. It gives the possibility to keep track of the entire sales activity. The process starts right from adding contacts of your leads and prospects and continues with creating sales orders, invoices and inventory managing sales and management on online marketplaces.

Monitor purchases | From item management to order fulfillment

Add vendor details to your contacts and manage all your online bills plus inventory purchase orders in a single place. Automated inventory management system makes your buying and procurement process more effective while creating backorders or even converting your sales inventory orders into separate simple material drop-shipments.

Track items, intensify procurement

Tracking the movements of inventory items, whereabouts, along with the expiry date is the additional functionality of inventory management software. One can add the serial or batch number with an automated system for inventory control. Besides, when you ship products or materials to a buyer, the inventory goods are tracked until delivery.