Time is money. We save both

A human is involved in any step of production: either performing it or controlling. We focus on a person as an important factor affecting the production. And you get a solution to reduce the number of human errors and boost productivity of your workforce.

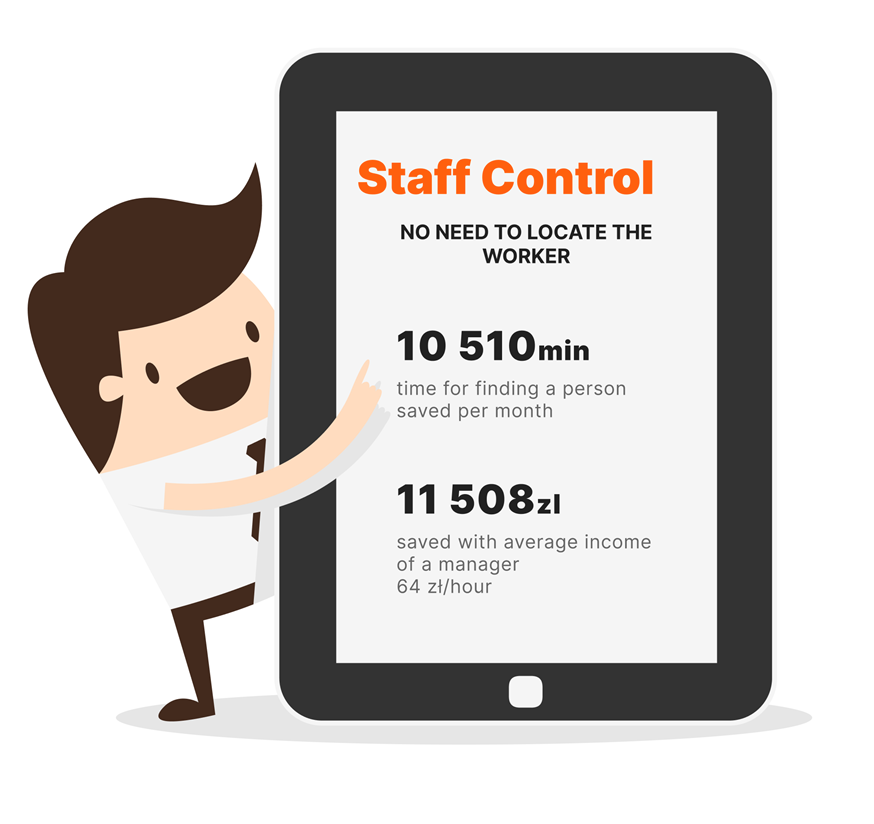

STAFF CONTROL

How to keep processes on track? Each minute counts, if you go for producing items according to predetermined Takt Time (Takt Time is the rate at which you need to complete a product to meet customer demand). But what if there is no enough material in stock? It means delays and increased lead time, that can ruin reputation of the comany. To avoid this, automatic system to replenish inventory in time comes in handy. Automation implies minimization of human-machine interaction, and we can say that the future is behind inductrial digitalization. Nevertheless, currently operations in numerous manufacturing facilities are being performed manually and involved continuous monitoring by managers. And now there is a need to control not only processes, but also employees!

Let’s take 5 min as the average time to locate an employee, if they are not at their workplace.

Do you know how much time a manager saves every day by using Staff Control to determine where, for example, 10 of his subordinates are?

| Number of subordinates |

Daily time savings, min |

Monthly time savings, min | ||

| Staff Control |

1 Manager |

10 | 10 * 5 = 50 | 50 * 21 = 1050 |

|

10 Managers |

100 | 100 * 5 = 500 | 500 * 21 = 10 500 | |

| Money saved in zł*: | 11 508 | |||

* According to Glassdor.com, the average salary of a production manager with 1-3 years experience in Warsaw is 132,624 zł/year or 65.7 zł/hour.

IDLE CONTROL

The logic is simple: an employee is absent from his workplace - the work is not done. The software - Idle Control - allows you to detect and record the fact of downtime. Managers can use this data to motivate staff to complete their tasks. If staff members use time inefficiently, then interfere and change the situation. Look how much time and money you can save with Idle Control!

| Detected time when staff is out of work, min | |||

| Per day | Per month | ||

| Idle Control | 1 Worker | 30 | 30 * 21 = 630 |

| 100 Workers | 3 000 | 3 000 * 21 = 63 000 | |

| Money saved in zł**: | 21 105 | ||

**According to Glassdor.com, the average wage of a warehouse worker in Warsaw is 3,377 zł/month or 20.1 zł/hour.

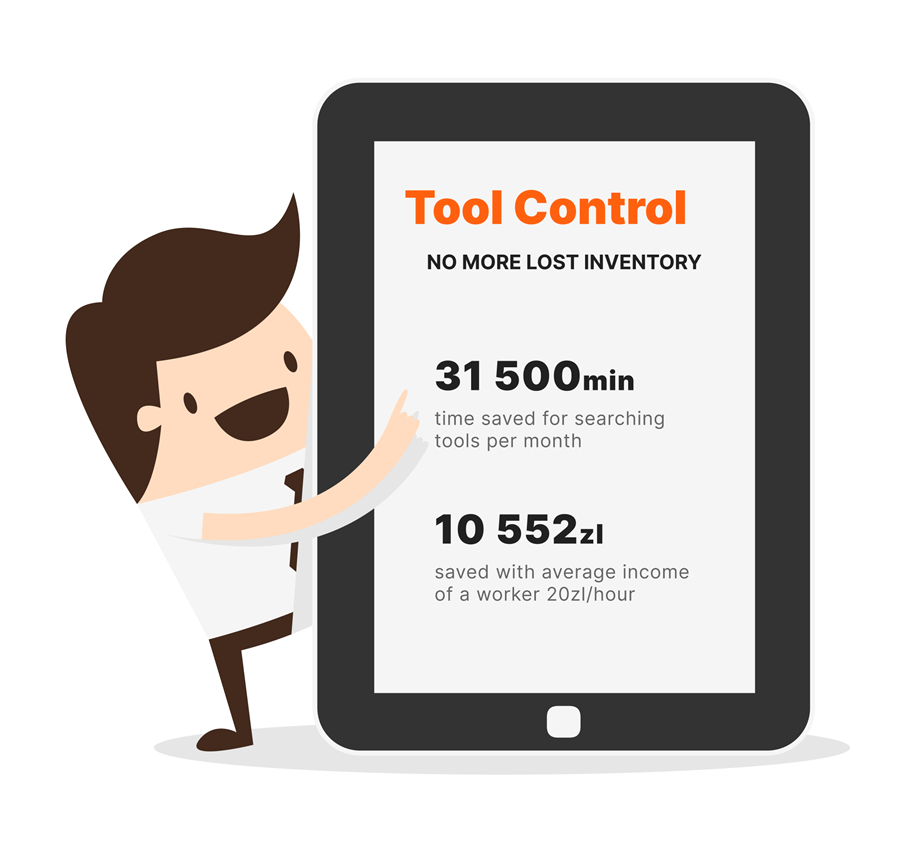

Tool Control

In production, there is often a need to clean up after yourself. A worker picks up a broom, cleans up, and leaves the broom near the machine - that is, without returning it to its place. Then his colleague, who needs a broom, will spend time looking for it because the broom is not in its place.

This is just an example that demonstrates the frequent search for lost and forgotten inventory in the production area. It’s time to use ToolControl!

| Average time saved with ToolControl on searching lost inventory, min | |||

| Per day | Per month | ||

| Tool Control | 1 Worker | 15 | 1 5 * 21 = 315 |

| 100 Workers | 1 500 | 1 500 * 21 = 31 500 | |

| Money saved in zł**: | 10 552 | ||

Learn more about AI-powered solutions for lean business management by 5S Control: SOLUTIONS