Control of PPE use

Control of Personal Protective Equipment use in manufacturing. Why is it so important and how is it realized?

Fewer accidents — fewer injuries

Falling debris, sharp materials, chemicals, noise…. There are lots of potentially dangerous situations at a production site that cannot be eliminated or controlled. At the same time there is nothing more important than the safety of your workforce.

Personal Protective Equipment (PPE) is a catch-all term that describes a broad range of safety-orientated clothing and accessories. The type of PPE you need will depend on the hazards present in your workplace. Common items considered PPE include safety helmet, vest, gloves and noise-canceling headphones.

In this review, we will show an example of the implementation of a system for monitoring the use of personal protective equipment in production.

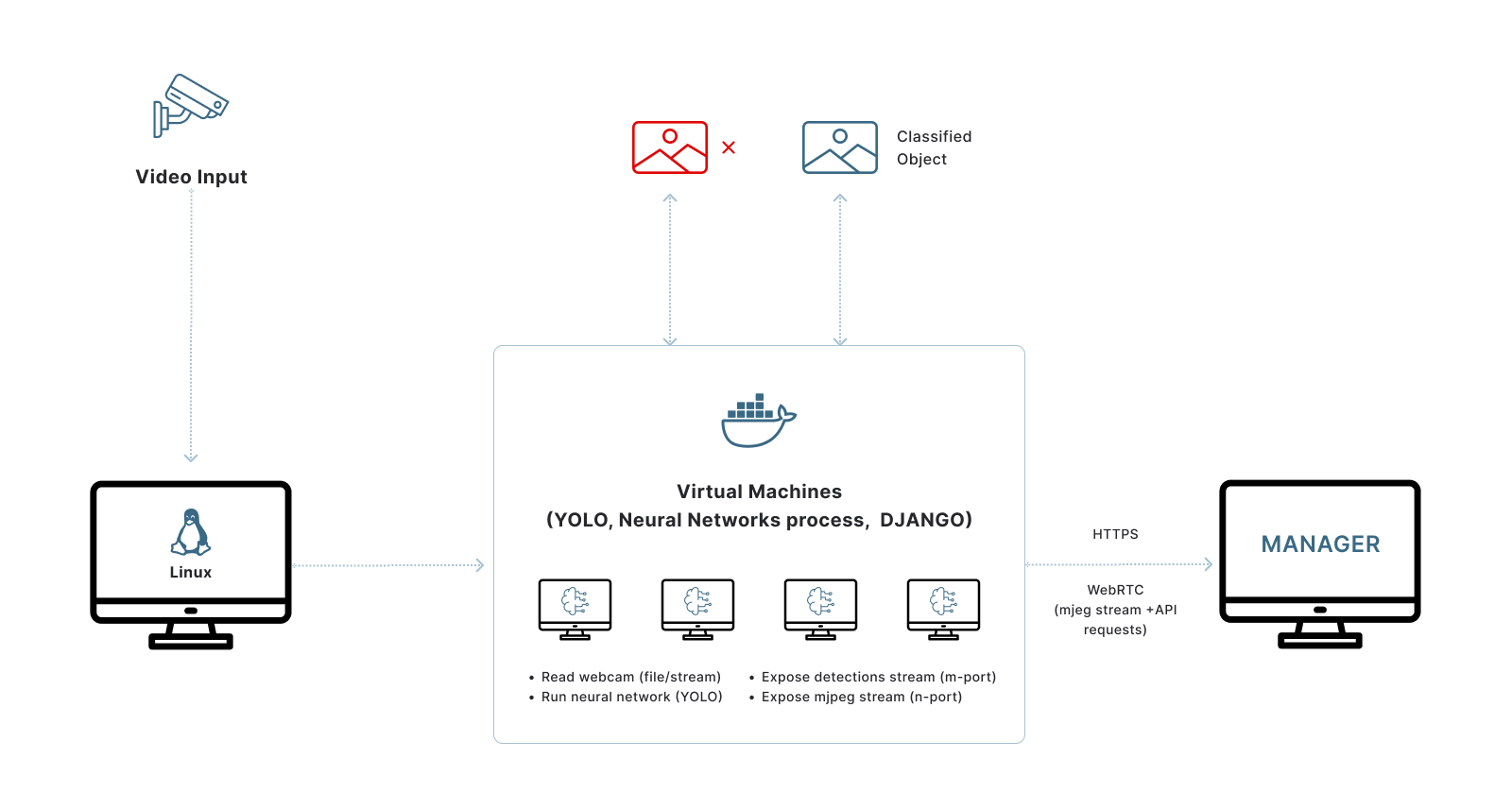

This solution is computer vision-powered. Computer Vision (CV) is a technology and trend in artificial intelligence that uses features of machine learning and deep learning to enable a computer to see, recognize and classify objects in the world around it.

At the production site, CV can effectively determine whether a worker is using protective equipment or not. Clear monitoring will help to avoid accidents and injuries.

So, let's have a look:

1. DATA COLLECTION

The first step is data collection. We need image files of certain formats. Why and what for?

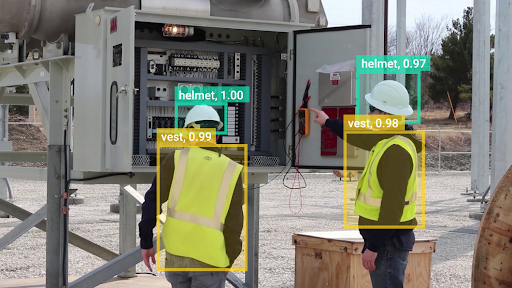

We're going to use them to feed a very-very smart thing -- YOLO! You Only Look Once (YOLO) is a state-of-the-art, real-time object detection system.

To train YOLO, photos of a worker with and without a safety helmet (for example) are made. The minimum number of images is 1000 (the more - the better).

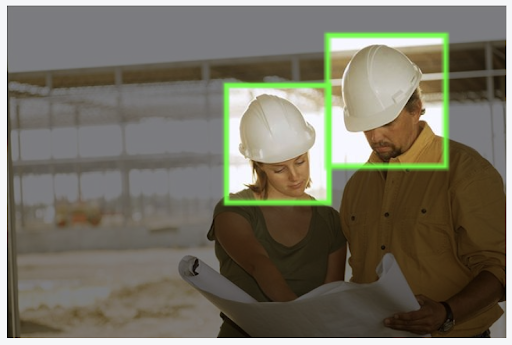

Examples of defined objects:

2. DATA PREPROCESSING

Now it is time to label and annotate each photo in order to give the computer vision model information about the objects present in the image. This stage is crucial for correct predictions. To graphically mark images a free open-source tool is used.

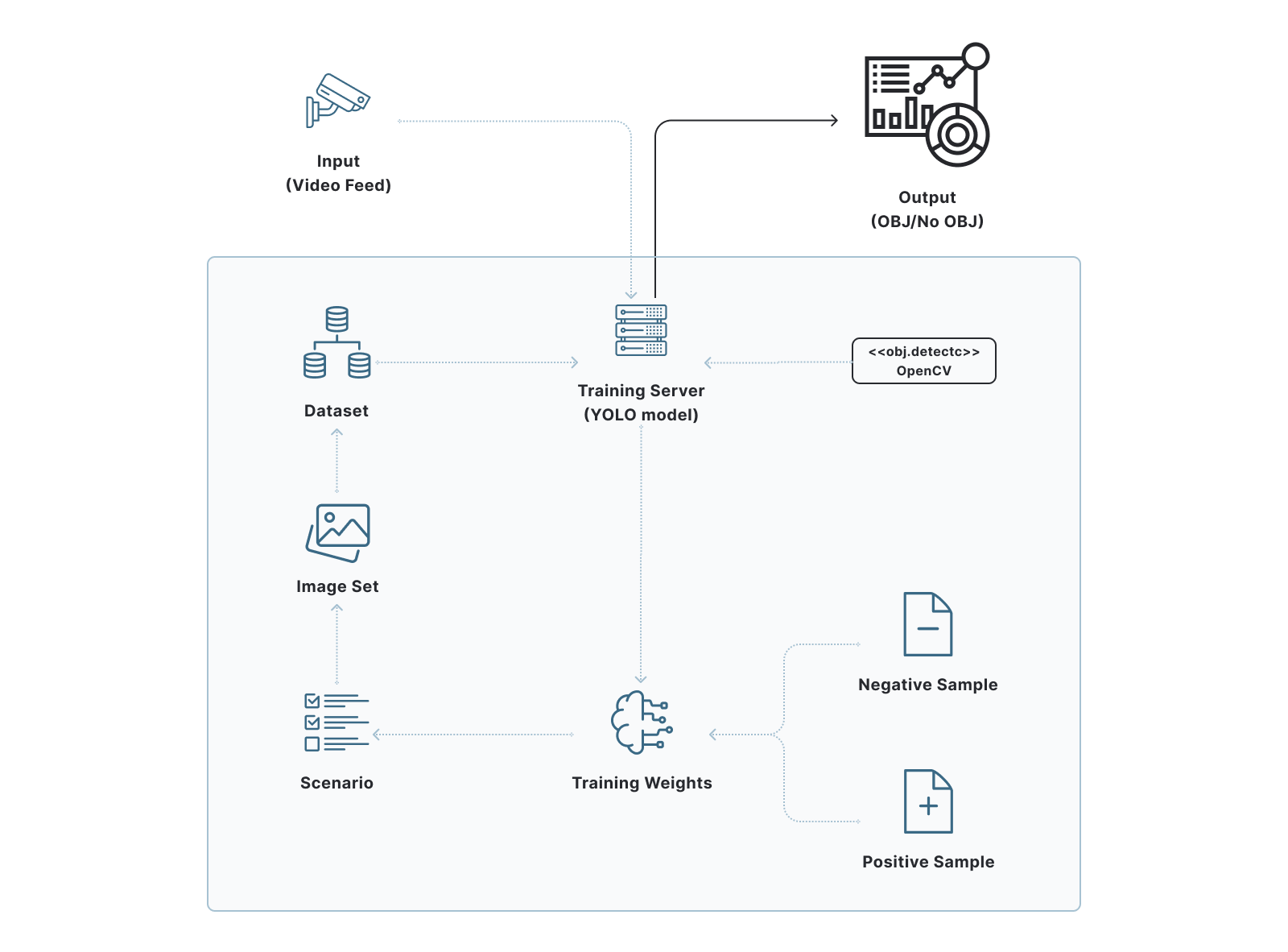

3. TRAINING THE MODEL

Here we’re going to work with TensorFlow -- an end-to-end open-source platform for machine learning. It is used for a variety of tasks with a focus on the inference and training of deep neural networks.

4. TESTING THE MODEL

Java Script (JS) is used for testing. In real time, an object is detected and compared to the trained model. There are several levels of the detection process (image obtaining, features extracting, etc.). The processed images are available to registered users at any time. All data is secure and protected.

GENERAL OVERVIEW

To sum up

As manufacturing facilities undergo digital transformation, more and more companies edge towards automating tasks and processes. This automation is also a key strategy for improving safety on the factory floor.

Control of wearing personal protective equipment can help workers feel more comfortable while performing their tasks, which can lead to increased productivity! And here is comes Safety Control!