PVC windows production

5S Control - let's get acquainted!

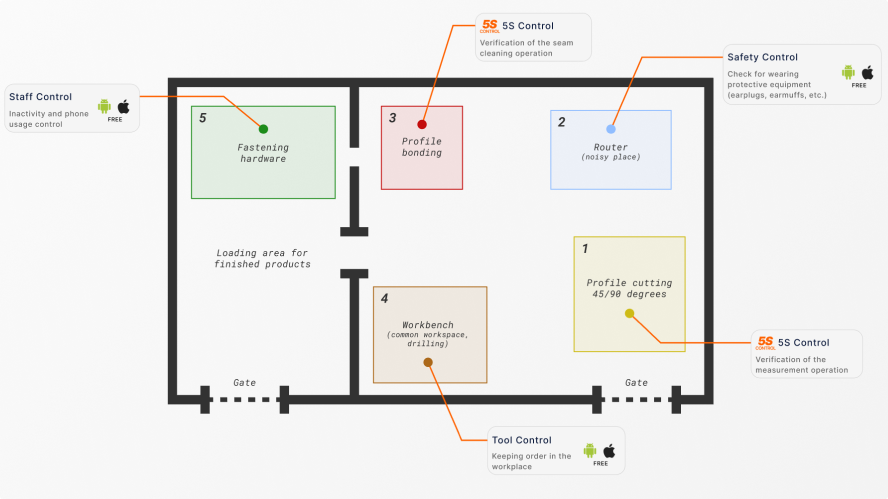

What is 5S Control in practice? How does it work and what are its benefits? Let's answer the latter question right away. The implementation of 5S Control free solutions suite is the way to reduce number of errors and cases that negatively affect the production.

So, let’s take PVC windows production as an example.

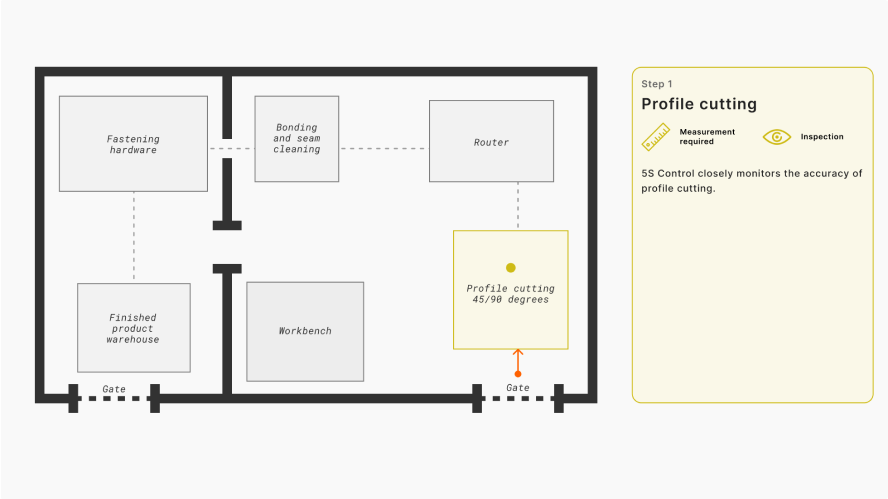

1. Profile cutting

1. Profile cutting

The machine at a plant may occasionally make mistakes, and that is why every fifth time the result is checked. 5S Control constantly monitors accuracy and precision, checking against pre-set parameters. If anything goes wrong, the manager will be notified immediately.

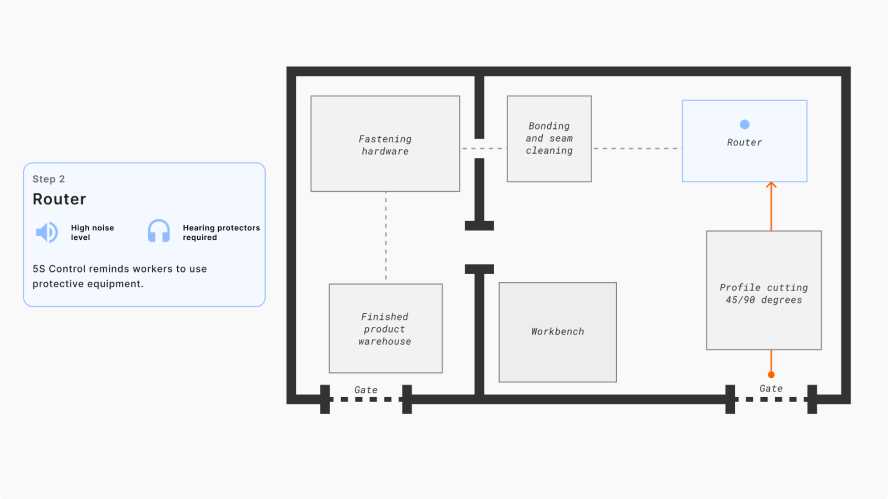

2. milling

2. milling

Machining in general is a risky environment for the employee. 5S Control ensures that the worker does not forget to wear personal protective equipment, notifying/warning if necessary.

3. Bonding and seam cleaning

3. Bonding and seam cleaning

At this stage the "human factor" often shows up and the employee accidentally misses one of the required operations. 5S Control tracks the actual number of seam cleaning operations performed. In practice, this data is checked against the process data for frame bonding. If the totals do not match, 5S Control informs about a deviation from the norm. This prevents the frame with an uncleaned seam from going further down the production chain. Thus the defect product will never reach the customer. The notification system for missed operations can be configured individually and can be set up easily by the user.

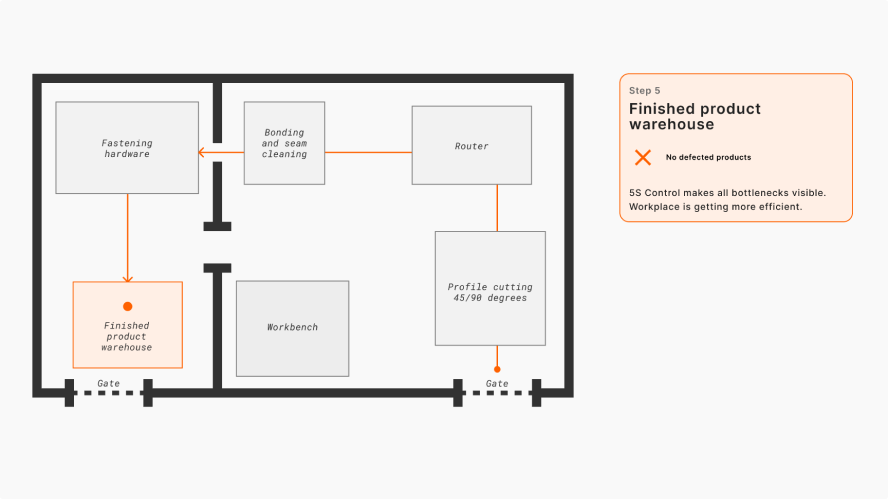

From raw material to shipment of the finished product

5S Control makes sure that employees are not distracted from their duties or spend time chatting or scrolling through their smartphone.

With 5S Control you get

easier certification (5S Control allows you to maintain constant compliance with standards, you are not afraid of sudden inspections)

greater customer loyalty

more responsible employees

growth of asset value

higher profits